Simply speaking, the system could be described as a connection of individual devices by means of the Internet in absence of any human being. In principle, data is collected from various sensors and shared via the Internet for further processing and evaluation.

Experts estimate 20 billion IoT devices to be operated worldwide by 2020.

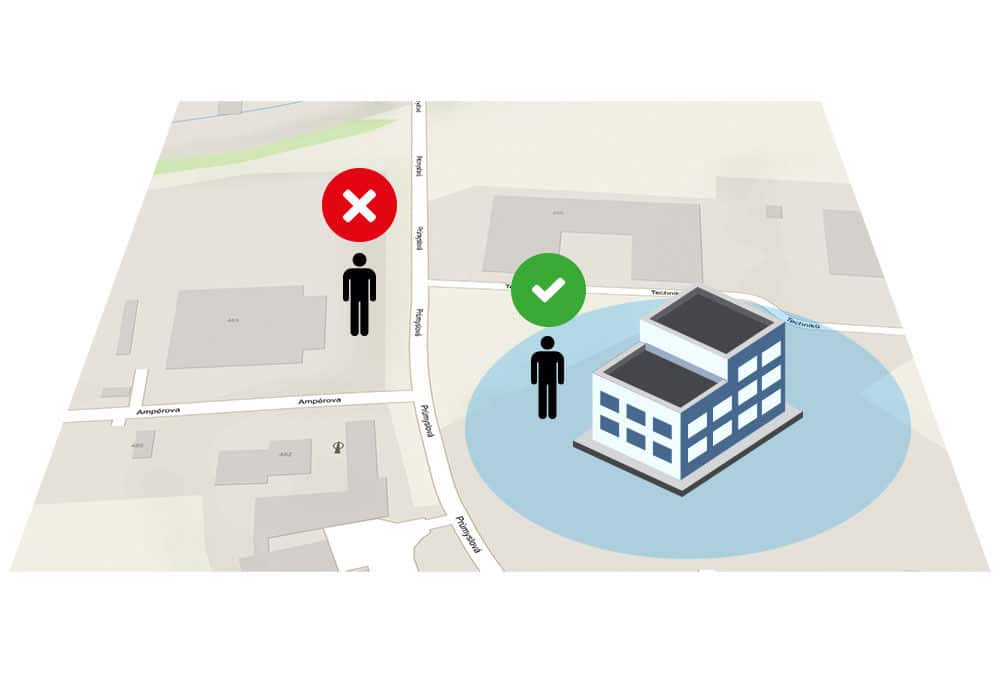

System for checking employee’s location

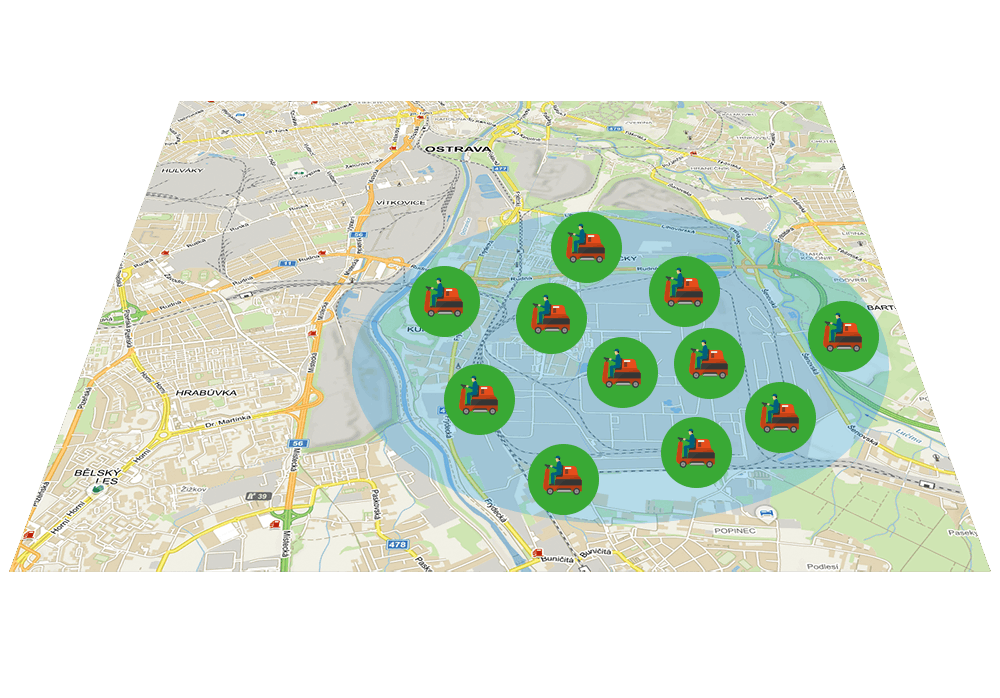

System for mobile machines monitoring

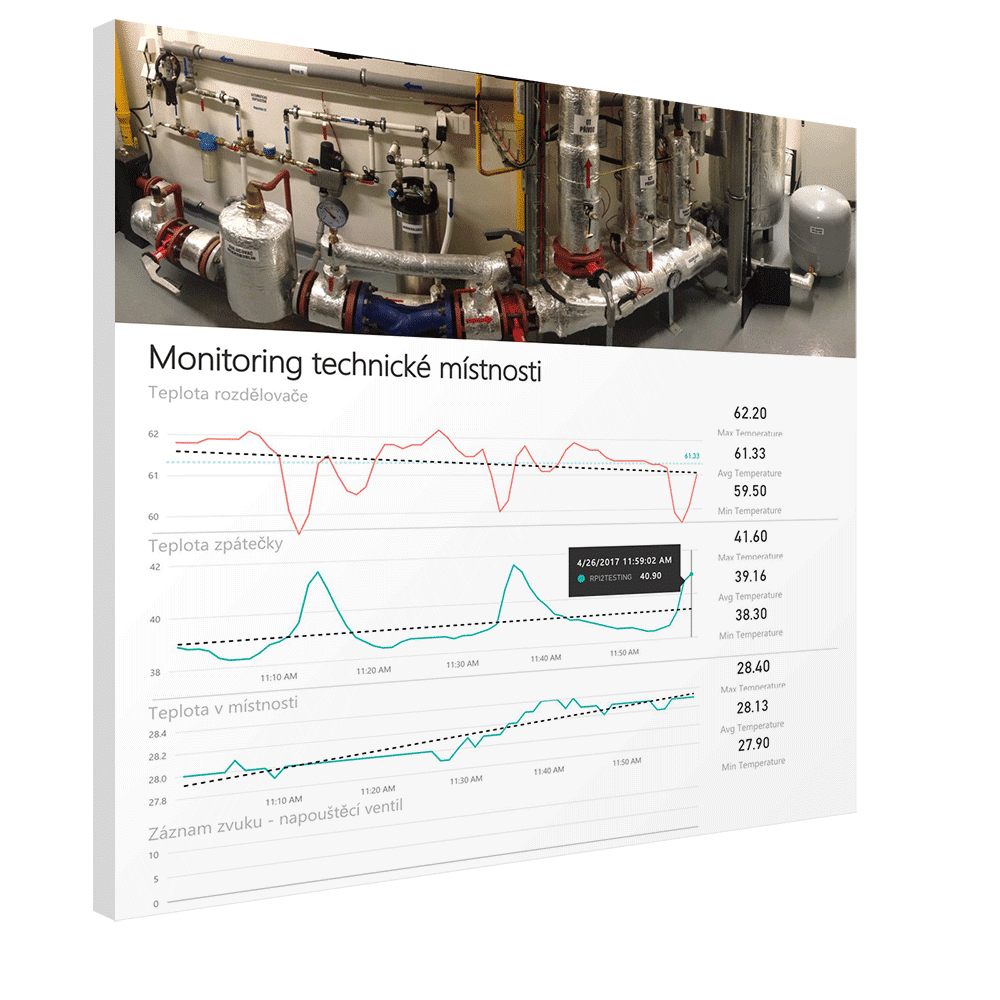

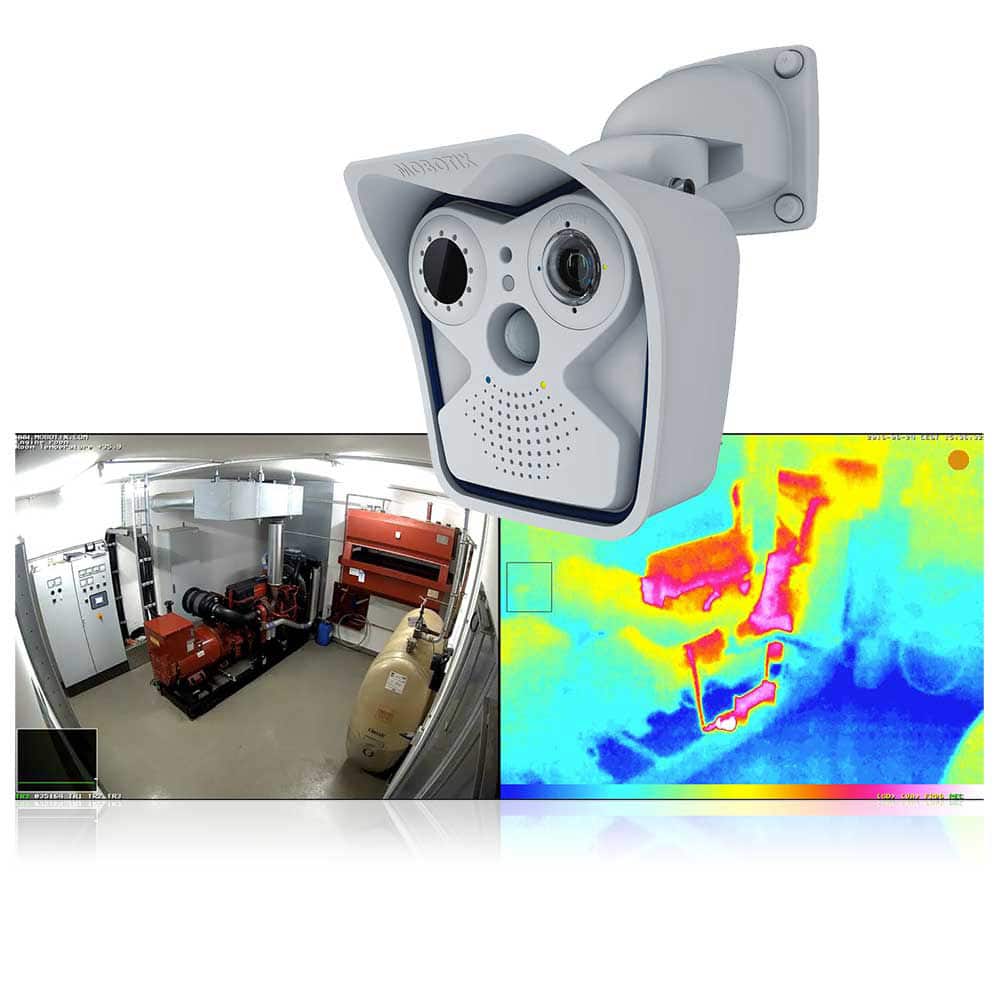

System for monitoring technical devices condition

System for technical devices monitoring

System for remote monitoring of specific devices

System for remote metering of measuring devices

System for scheduling dynamic cleaning

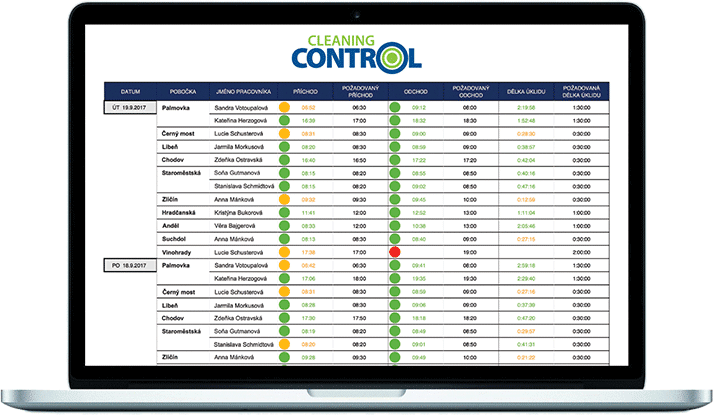

System for tracking cleaning operators’ attendance

Extremely low power consumption

Low purchase price

Transparent roaming

High signal penetrability

Two-way communication

Country-wide coverage (CR)

Geofencing, also called Circuit participation check, is the system monitoring employees’ location (i.e. whether they are in the places assigned). The monitoring is ensured via a company mobile phone that is sending time and location data, using GPS. Consequently, it provides us with information on the relevant employee’s location and on the time he came there and left.

The employees push the ENTRY button...

...and place their chips to the box.

When leaving, they just press the LEAVE button...

...and again just place their chip to the device.